Business

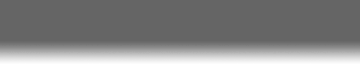

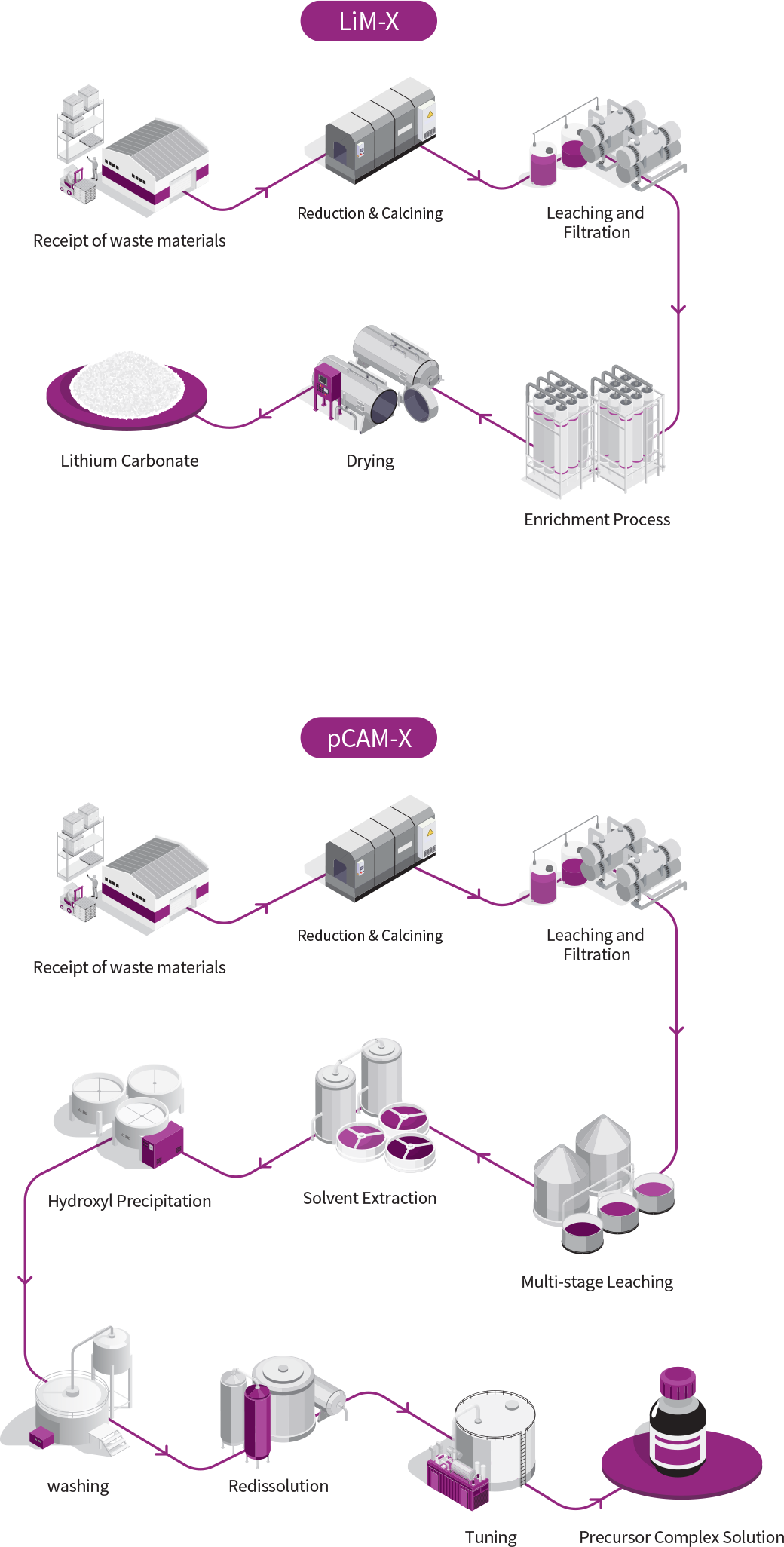

Sebit Process Chart

Main Processes of Battery Recycling

Introduction of item

-

Precursor Complex Solution

· It is a high-purity nickel-cobalt-manganese sulfate complex solution produced by refining by solvent extraction method. It is manufactured by recovering valuable metals from discarded waste batteries and defective cathode materials, and can be produced by adjusting the ratio of nickel, cobalt, and manganese at the request of the customer.

-

Black Mass

· Sebitchem manufactures recycled cathode materials by collecting waste cathode materials generated in the secondary battery cathode material production process and then removing impurities. It is a black powder containing rare metals, such as nickel, cobalt, manganese, and lithium, and has high recyclable economic value as a cathode material for secondary batteries.

-

Lithium Carbonate

· Lithium carbonate is a material that makes up the cathode material and electrolyte of secondary batteries. As a core mineral for secondary batteries, it accounts for 40% of the manufacturing cost of secondary batteries and serves as a positive ion that moves electrons. Due to its high purity and granularity, SebitChem's lithium carbonate is popular as a secondary battery material for ESS or EVs.

-

Lithium Phosphate

· This product recovers the remaining lithium in the form of lithium phosphate after extracting valuable metals such as nickel and cobalt. Compared to lithium carbonate produced by SEBITSHEM, it has a slightly higher level of impurities and is less soluble in water.